Ensure CE Compliance for Pressure Equipment with Kiwa

Receive a quote tailored to your needs

Why pressure equipment certification matters

Pressure equipment that is not properly designed or manufactured can pose serious risks to people, property, and the environment. The PED provides a strict regulatory framework to minimize these risks and to ensure that only safe, compliant products reach the market.

Kiwa’s PED certification services help you demonstrate that your products:

- Comply with EU safety regulations

- Meet technical and performance standards

- Are safe to use and built to last

- Can be legally traded within the EU with the CE mark

Product certification and CE marking

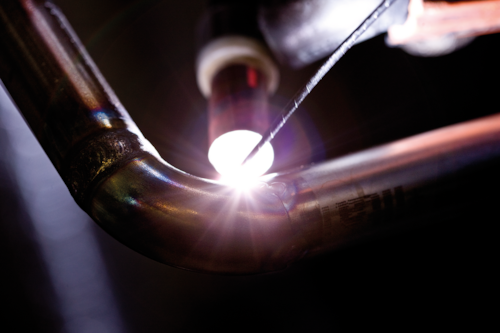

We provide product certification and approval for a wide range of pressure equipment. Our experts review technical documentation (such as design drawings and material specifications), inspect manufacturing processes, and conduct or witness required testing. Once conformity is confirmed, you gain the right to affix the CE marking to your product. This is a legal requirement for selling pressure equipment within the European Economic Area.

Examples of pressure equipment Kiwa certifies

- Pressure vessels

- Heat exchangers

- Steam generators

- Boilers

- Autoclaves

- Pressure accessories (e.g., safety valves, gauges)

- Piping systems

- Assemblies with multiple pressure components

Module B – EU Type Examination

EU type examination is an option for high-risk categories. With a type certificate, the design can be a required step. This module involves an assessment of a representative design or prototype by Kiwa. If compliant, we issue an EU Type Examination Certificate. This certificate forms the basis for production and additional modules.

Quality System Certification

In addition to product certification, we offer Quality System Certification under PED. This method shifts the focus from inspecting individual products to evaluating the manufacturer’s entire quality management system.

Benefits of PED quality system certification:

- CE marking based on internal production controls

- Reduced need for repeated inspections

- Ideal for serial production or batch manufacturing

- Includes regular audits and surveillance by Kiwa

CABF Recommendations

Benefits of working with Kiwa

Independent Notified Body

Comprehensive certification support

Streamlined tailored procedures

Enhanced trust

Clear communication

OEM and Equipment Compliance Solutions

Ensuring compliance for Original Equipment Manufacturers (OEMs) is essential for market access, safety, and regulatory adherence. Our comprehensive solutions cover certification, design validation, welding assessment, vendor inspections, material testing and pressure equipment approval, helping manufacturers meet international standards while enhancing product quality and reliability.

Hydrogen Systems Compliance and Safety

The rapid expansion of hydrogen as a clean energy vector requires strict safety measures, material compatibility, and regulatory compliance. Our hydrogen systems comprehensive services ensure safe storage, transport, and application through rigorous material testing, high-pressure assessments, and compliance with global hydrogen safety standards.

Frequently Asked Questions

What is a Notified Body?

A Notified Body is an organization appointed by an EU country to help make sure certain products meet the right requirement before they can be sold. These organizations play an important role in checking that products follow EU rules by carrying out tasks like testing, inspecting, and certifying them.

What is the Pressure Equipment Directive (PED)?

The PED 2014/68/EU is a European product safety directive that sets technical requirements for pressure equipment operating above 0.5 bar. It ensures products are safe for use and legally marketable in the EU through CE marking.

Which products fall under PED certification requirements?

Products like pressure vessels, boilers, heat exchangers, steam generators, autoclaves, safety accessories (valves, gauges), piping, and assemblies are commonly subject to PED requirements.

What is CE marking and why is it important?

CE marking is a legal requirement in the EU for pressure equipment above 0.5 bar. It shows that your product complies with the essential safety requirements of the PED and allows it to be sold across the European Economic Area.

What is Module B in the PED certification process?

Module B is the EU Type Examination process. It involves evaluating a prototype or design of the pressure equipment to confirm it meets PED safety standards.

Can Kiwa certify our internal quality system under PED?

Yes. Through Modules D, E, or H, we can certify your quality management system. This allows you to CE mark your products based on internal production controls, streamlining the process and saving time.

How long does the PED certification process take?

The duration depends on the complexity of the equipment, the conformity assessment module chosen, and the quality of your documentation. Kiwa ensures efficient processing and transparent timelines.

ISO 9001 Quality Management

ISO 9001 Quality Management Systems Certification with Kiwa: improve your performance, meet customers’ needs and increase your profit.

ISO/TS 19880-1 for Hydrogen Fueling Stations

Hydrogen is slowly becoming the go-to transition low carbon fuel for transportation. To fuel the hydrogen engines, owners of petrol stations are either developing or investing in hydrogen fueling stations. To do this in a safe and harmonized way an international standard was developed: the ISO/TS 19880-1.

OCP Personnel Certification

Get certified to EN ISO/IEC 17024 with Kiwa, which specializes in certifying people in areas such as welding. Kiwa ensures impartiality and accessibility in the certification process.

EN 1090-1 certificate: your starting point for CE marking steel and aluminum constructions

EN 1090-1 certification with Kiwa: demonstrate your compliance with EU regulations, highlight the quality of your components and get ready to access the European market with CE marking.

EN ISO 3834 Welding Manufacturing Certification

Welding is a special manufacturing process which is used in sectors to reveal structures which cannot be manufactured as one piece. The EN ISO 3834 series standards are also standards that define all Quality requirements for the operation of this particular process.

EN 14015 – Inspection and assessment of design and manufacturing of on site built steel tanks

EN 14015 – Inspection and assessment of design and manufacturing of site built, vertical, cylindrical, flat-bottomed, above ground, welded, steel tanks.

Welding Management Test (WPQR - WPS)

WPQR is the process of examining the welding procedure during the compliance process according to the relevant standards (manufacturer's production, supervising the welding test, carrying out the testing procedures and evaluating them).

EEMUA 159 – Inspection, maintenance and repair of above ground flat bottomed storage tanks

EEMUA 159 – Inspection, maintenance and repair of above ground flat bottomed storage tanks.

Storage Tank Calibration

Kiwa provides accredited tank calibration and inspection using advanced 3D scanning technology. Ensure measurement accuracy, regulatory compliance, and operational efficiency—all delivered in a single, streamlined service.