Tank Inspection

Receive a quote tailored to your needs

The Challenge

In today’s complex industrial landscape, tank inspections and pressure vessels have become increasingly challenging. Organizations face mounting pressures from stricter regulatory requirements, escalating safety standards and the need for more sophisticated asset management. Regulatory inspections of storage tanks often still rely on traditional methods. These involve a patchwork of human inspectors, individual drone/robot operators, and various specialist companies. This fragmented approach creates significant bottlenecks, compromising the effectiveness and efficiency of your inspection process.

The result? Longer outages, higher inspection costs, potential safety risks, and inefficient data collection. Meanwhile, regulatory requirements for reliability and compliance grow stricter each year, putting additional pressure on your operations.

The Solution

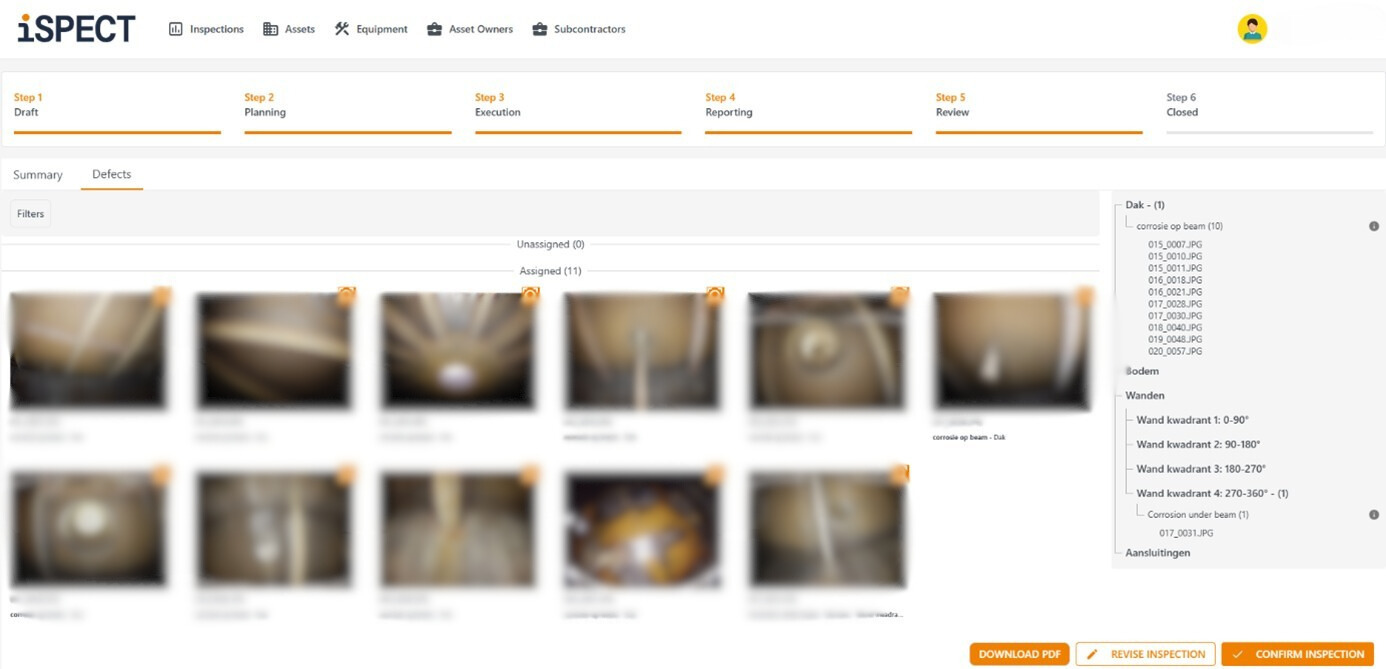

We introduce a comprehensive, technology and AI-driven tank inspection solution that transforms how industrial organizations manage their critical infrastructure.

Our Integrated Inspection Ecosystem Delivers:

- Total insight (SPOC) into tank condition through multi-dimensional data integration

- Consistent, comparable defect analysis

- Optimized inspection planning and execution

- Full regulatory compliance with *Fully Compliant with API 653, EEMUA 159, Vlarem (BE-VL), Codex (BE-Wal) and PGS 29/31 (NL)

- Centralized digital inspection platform

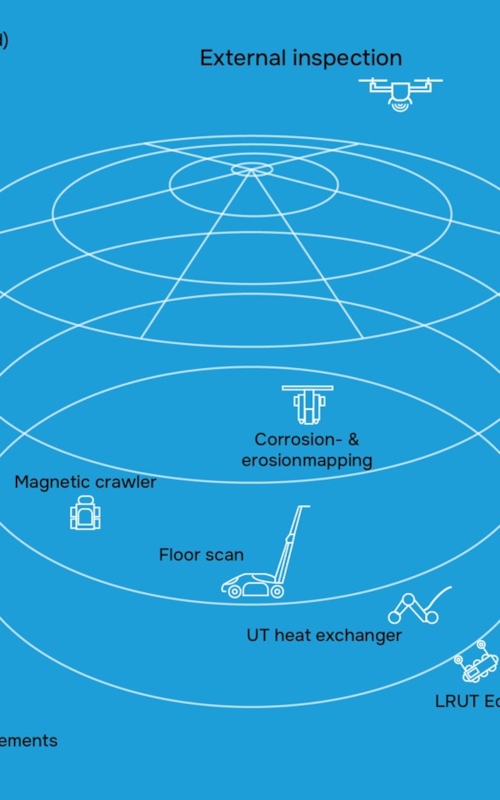

Technical Approach:

- Drone and robotic inspection technologies

- Advanced NDT techniques

- Visual, Thermal, Scanning: Ultrasonic (UT), Pulsed Eddy Current (PEC), Phased Array (PA)

- Emission: Optical Gas Imaging (OGI) & sensor technology

- Measurements: Lidar

The Impact

By choosing our comprehensive solution, you’re not just streamlining your inspection process, you’re transforming it. The benefits of our solution extend far beyond traditional inspection processes.

Operational Advantages:

- Reduction in inspection time

- Lower inspection-related costs

- Enhanced workplace safety

- Real-time, actionable insights

- Predictive maintenance capabilities

Our digital inspection platform transforms compliance from a complex obligation into a strategic asset, enabling proactive risk management and predictive maintenance capabilities.

By centralizing all inspection data and providing real-time, actionable insights, we help organizations shift from reactive maintenance to a forward-looking, intelligent asset management strategy.

Our solution doesn’t just meet your current needs. It anticipates future challenges in tank inspection and maintenance, positioning your organization at the forefront of industry best practices.

Related Services

Inspection

EEMUA 159 – Inspection, maintenance and repair of above ground flat bottomed storage tanks

EEMUA 159 – Inspection, maintenance and repair of above ground flat bottomed storage tanks.

Inspection

EN 14015 – Inspection and assessment of design and manufacturing of on site built steel tanks

EN 14015 – Inspection and assessment of design and manufacturing of site built, vertical, cylindrical, flat-bottomed, above ground, welded, steel tanks.

Inspection

Commodities Act Pressure equipment Modifications (Operational stage)

During the operational stage of pressure equipment it can occur that a pressure device requires modifications. In that case, the user needs to take necessary measures regarding the modifications to the pressure equipment.

Certification, Inspection, Testing

Non-Destructive Testing (NDT)

Check if quality demands are being met with non-destructive testing. Or use NDT testing as part of in-service inspections or preventive maintenance to quantify the status of critical components and equipment.

Digital solution, Testing

Digital radiography and digital X-ray inspections

Kiwa has taken the development of digital X-ray imaging, or radiography, even further. Using a Digital Detector Array (DDA), digital X-ray imaging can be performed without disturbing the normal functioning of the environment.