Well Certification

Kiwa provides a broad range of services in the Oil, Gas and Chemicals sector to help you make sure your operations and employees, plants, storage systems, (transport) pipelines and other facilities are in optimal condition. We participate during maintenance stoppages and in your renovation, modernisation and investment plans. This allows you to minimise risks, maximise safety, uptime and sustainability and face challenges - today and tomorrow.

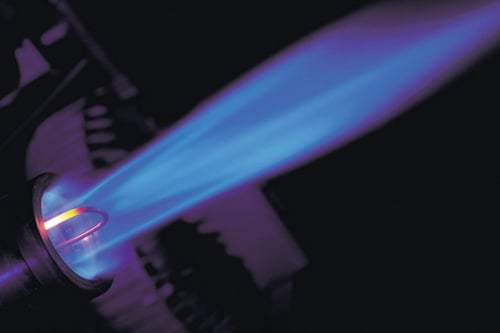

We execute process equipment inspections to ensure the safety of pressurized equipment, furnaces, cracking refineries, storage tanks and pipelines. The assessments are based on legal requirements, on your process information, non-destructive testing and our empirical knowledge. The inspections evaluate and define:

When all the important information is collected during the inspection, the data can be used to manage the lifecycle of the equipment and to define the necessary procedures during the equipment its lifecycle. In this way you as a manufacturer have a good overview of the risk factors, the details of repair and maintenance procedures and can develop focus points for the upcoming period.

Modern technology paves the way for new advanced techniques to test, inspect and certify your equipment even better. Our experts are always up to date on the latest developments in the field. That’s why our services include drone inspections, leak inspections, lifecycle analysis and process and automation safety.

For material inspection we make use of destructive testing (DT), damage examinations and lifetime analyses. Together with you, we map out the best path to follow. All this to ensure safety, quality and health and to minimize downtime for you.

Projects like turnarounds, modifications and greenfield construction can be very complex. At Kiwa we have experts who can support you. Our international pool of inspectors and operators cover the entire Northern European region. This enables us to provide full scope inspection services to large capital projects in the region. Such as vendor inspections, QA/QC, pressure equipment inspections, welder certification, material testing and NDT.

Would you like to know more about our services in the field of Industrial Services? Please contact us using this form.