Utility Mapping: What It Is and How It Can Be Used in Damage Prevention

The following article was published as a feature article in the June/July 2025 issue of Trenchless Technology magazine, authored by T2 Utility Engineers’ Shauna Weinmann, PE and Aline Melo LeBlanc. The article highlights the intended value as well as the limitations to be aware of when choosing Utility Mapping for documenting underground utilities.

The authors provide an overview of additional methods to consider for damage prevention and best practices for Horizontal Directional Drilling as well as professional insights.

What is utility mapping?

Utility mapping is recognized as the process of identifying, locating, and documenting underground utilities without a standard or agreed-to process. Given the lack of standard, the term itself can be confusing. We hope to explore the value utility mapping can have for asset management, but also where it is lacking or inconclusive in the utilities it depicts.

For instance, if the map was based on geophysics, it may be limited by equipment and not include comprehensive ground penetrating radar (GPR). The mapped results may be surveyed but may not be thoroughly reviewed or reconciled relative to records or as-builts. The utilities may not show a size, material, type, or be labeled whether they were geophysically located or drawn based on records.

Artificial intelligence (AI) may also create utility maps within minutes using online information that may be of questionable accuracy. Just because it is online doesn’t mean it’s true. Without geophysical verification or visual confirmation (potholes) the information provided is schematic at best.

The value of utility mapping is to show apparent utility location information within the project limits. This information is heavily relied upon in the One Call industry and can often be easily referenced through GIS or other quick data repositories.

Clarifying Limitations:

- Utility mapping does not search for unknown utilities.

- Abandoned, undocumented, or smaller utilities may be missed.

- Professional guidance or oversight may not have been used during utility map creation.

- The utility map may have been created by a tech savvy AI or bot, which could lead to misinterpretation and inaccuracies leading to further problems.

Who is responsible and pays for damages if the information is wrong and a utility is hit?

Other methods for obtaining below-ground information include:

One Call/811/Call Before You Dig/Blue Stake

Many states or provinces have laws in place to locate “publicly” owned, operated, and maintained underground utilities before any excavation. These services are known by multiple names, depending upon location. The goal is to provide a first step in damage prevention for smaller or homeowner projects to reduce risk of injury, utility outages, and expensive repairs, however, not all utility companies participate and often private lines will not be marked.

Before we explore further, some points to clarify:

- Utilities depicted in GIS are primarily meant for asset management, not damage prevention.

- One Call Services relies on one pipe and cable locator. That is frequently insufficient and relies too much on one methodology.

- Software alone, cannot accurately track or depict all utilities given the frequent installation, removal, and repairs occurring daily across North America.

- One Call marks that are painted on the ground and then surveyed are not considered SUE QLB.

- One Call only marks active utilities, overlooking decommissioned, abandoned, or inactive lines.

Subsurface Utility Engineering (SUE)

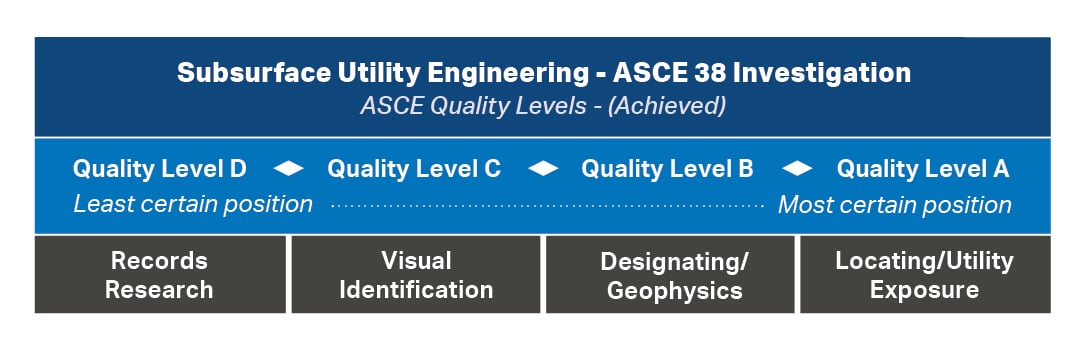

SUE is based on established procedures that must be followed to be considered compliant. The ASCE 38-22: Standard Guideline for Investigating and Documenting Existing Utilities provides a nationally recognized guideline for the collection and depiction of existing subsurface utility data.

A Quality Level value is assigned by the responsible licensed professional to each utility segment to indicate the relative certainty in the depicted position resulting from the utility investigative effort and the engineer’s professional judgement. This level of effort provides more reliable data, should a project require that.

There is value in experienced, trained, and knowledgeable underground experts to locate existing utilities within inches and providing the information in advanced formats.

HDD Utility Depictions

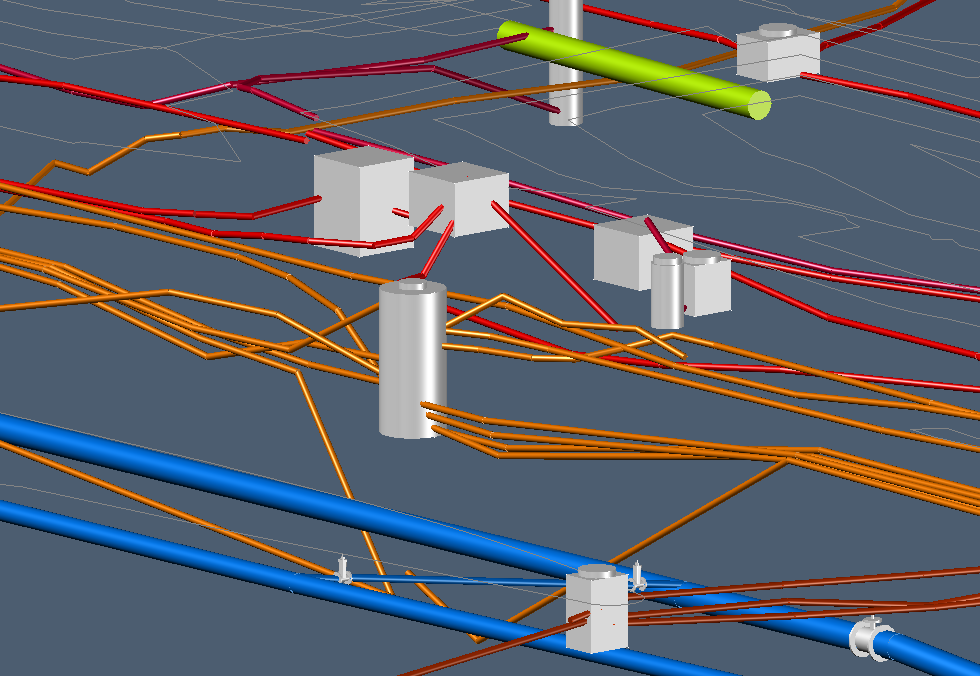

Horizontal directional drilling (HDD) has previously relied upon 2D depictions to navigate the complicated subsurface environment. Utilizing SUE data with reasonable assumptions can be incorporated into a 3D model depicting the depth of the utilities based on a few assumptions which includes electronic depths (e-depths) information, as-built drawings, inverts, industry assumed depths, and dig-ups (test pits), when available.

The electronic depths are collected in the field using electromagnetic locators or ground-penetrating radar. Depending on the material of the utility, the depth collected may be interpreted differently. Metallic pipes will have a stronger signal reflecting from the middle of the pipe, so the diameter of the utility must be taken into consideration when interpreting the depth into a 3D model. Plastic material pipes with tracer wire, will have their depth measured from the top of the pipe to surface. If a sonde was used, the depth will be interpreted from the apparent invert of the pipe. Electronic signals also may vary according to the type of the ground surface and soil. The depiction in image A shows an example of variation of e-depths in the same utility alignment. These variations are accounted for when creating assumptions in a 3D model and adapting the vertical alignment to appear more realistic.

Invert information, when available, is often utilized when modeling sewer pipes as well as top of pipes from water chambers and valves when available. From as-built drawings, invert data is also used to depict the depth of the utilities. However, 3D models are commonly tied into an existing surface created on a project-by-project basis, which is often inconsistent with elevations shown on older records data. It is important to examine these factors when evaluating depths from records drawings to build a subsurface utilities 3D model.

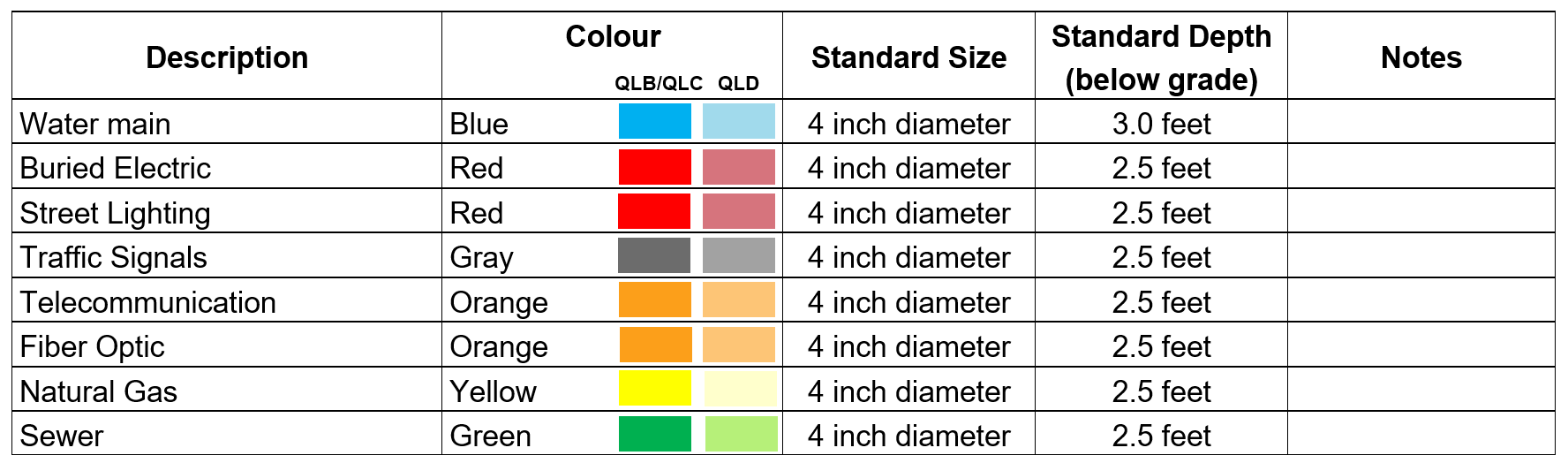

Industry assumed depths are typically used when no other data is available. Assumed minimum depths are shown as an example in image B.

(Image B)

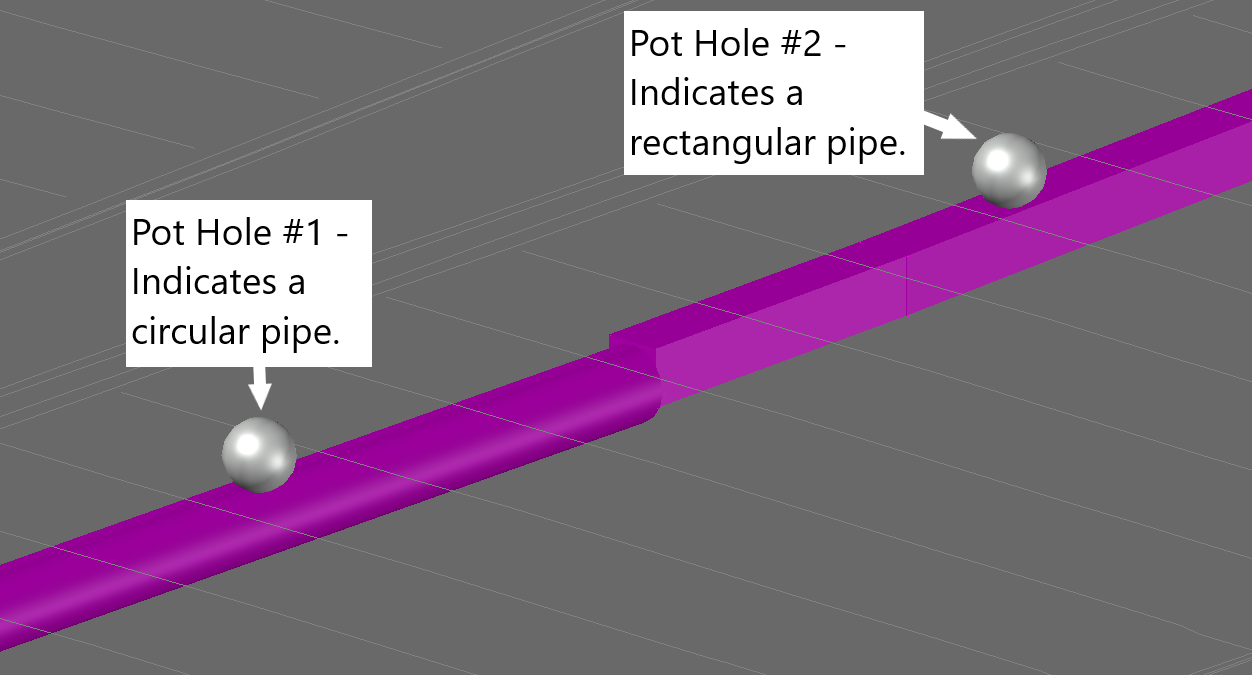

Lastly, when dig-ups data are available, utility size, material and depths shall be incorporated into the 3D model. The challenging point of this, is how wide the area, or length of the utility segment should carry this data especially when in conflict with other information such as utility records, industry standards depths, and electronic depths. Further, another pot hole in the same utility alignment, as shown in image C, can cause variations in the model.

(Image C)

(Image C)

The Goal Is Damage Prevention

The combinations of the utilities records information, electromagnetic depths, inverts, dig-ups and industry assumed depths, compiled, and interpreted all into one subsurface utilities 3D model is beneficial to increase the accuracy of the utilities alignments, both horizontally and vertically. Providing this beneficial information for the field work when directional drilling, utility daylighting, and open trenching is an important contribution for damage prevention.

Data gathered, whether through records or field investigations is essential for utility mapping which can ultimately be a useful tool for trenchless projects and damage prevention. This utility map can help with project planning to depict where utilities may be anticipated and may require exposure during construction for damage prevention to avoid cross bores. The data can also be used in/for layouts and direction drill path planning, ahead of field work and construction.

Key Takeaways from this article:

- Use utility data for decision making and planning but understand the limitations of each method.

- Use utility mapping and SUE for project planning to determine locations for utility exposure during drilling, to reduce risk.

- Reference ‘best practices’ for HDD and abide by state and province laws during excavation.

- Shauna Weinmann, P.E., is a senior project manager with T2 Utility Engineers, U.S.

- Aline Melo LeBlanc is the 3D modeling lead with T2 Utility Engineers, Canada.

- T2 Utility Engineers’ is a Kiwa company.

T2 Utility Engineers

T2 Utility Engineers specializes in services to reduce the risk of existing underground and above-ground utilities for infrastructure projects. Their mission is to provide reliable utility information, professional insight, and high-quality deliverables.

Subsurface Utility Engineering | Kiwa

Reliable underground and above-ground utility information is crucial for informed decision-making and the management of the risks related to existing utilities on infrastructure projects.