Top Performers, Hidden Risks: Inside Kiwa PVEL’s 2025 PV Module Reliability Scorecard

Every year, the PV Module Reliability Scorecard from Kiwa PVEL highlights the latest performance and reliability trends from our independent testing of solar photovoltaic (PV) modules. The Scorecard summarizes the key data from our Product Qualification Program (PQP), which subjects modules to a series of accelerated stress tests that simulate various real-world conditions. Notably, the Scorecard identifies “Top Performers” across each of our test categories, helping developers, investors, and procurement teams to make better-informed decisions that mitigate risk in their projects.

In the 11th Edition of the Scorecard, released in June of 2025, we named 50 module manufacturers as Top Performers, including nine who had at least one model listed as a Top Performer in all seven test categories. Being a Top Performer in the Scorecard is a powerful endorsement. It signals superior reliability to buyers and investors, which can help to differentiate in competitive procurement and assist with bankability considerations.

Out of more than 300 unique model types evaluated, only 21 achieved Top Performer status across all reliability tests (including Thermal Cycling, Damp Heat, Mechanical Stress Sequence, Hail Stress Sequence, PID, and LID+LETID)—and just 3 of those also excelled in PAN performance. The online Scorecard’s searchable database allows users to filter Top Performers by manufacturer, PQP test, module design, power class, and more.

The importance of PQP Testing

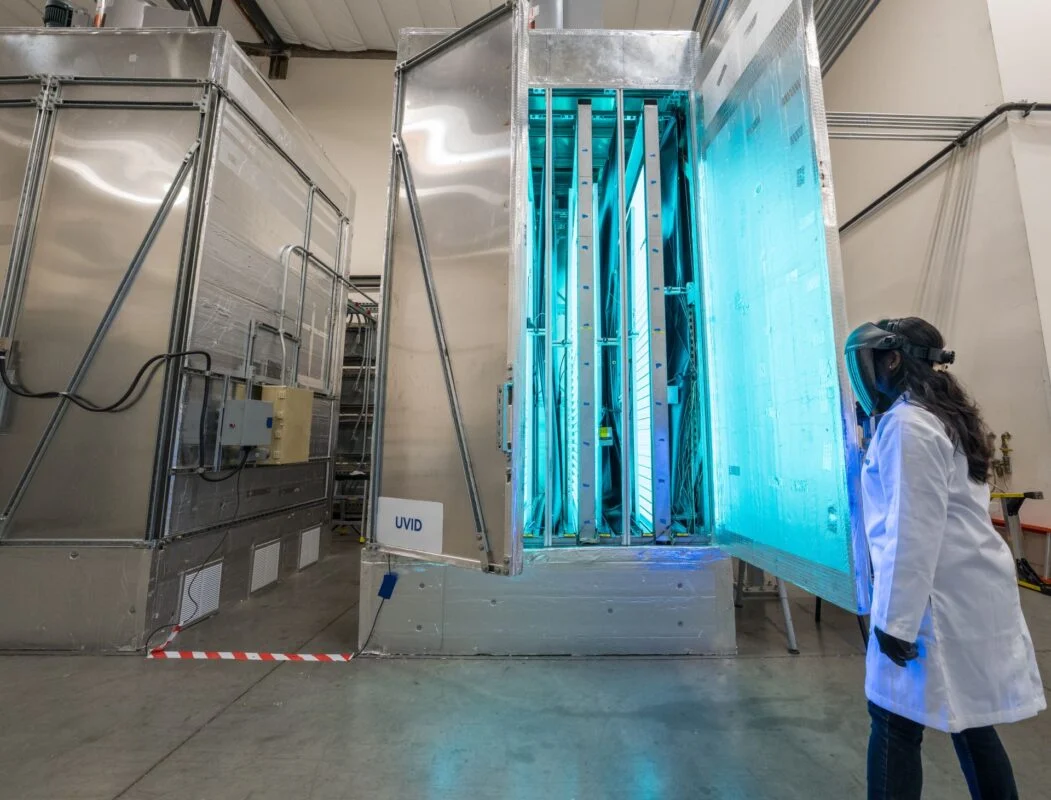

Changes in PV module designs and components can have big impacts on reliability and performance, and the industry’s certification tests are typically not rigorous enough to identify these potential issues. Module warranties often have shortcomings that leave site owners exposed to significant financial losses. Kiwa PVEL’s PV Module PQP is a comprehensive protocol of tests focused on addressing these concerns and helping module buyers achieve better procurement.

Kiwa PVEL evaluates each solar Bill of Materials (BOM)—the distinct combinations of components used to assemble PV modules. Since modules with the same model name can have different materials and components, Kiwa PVEL assesses each unique Bill of Materials (BOM) to ensure accurate, granular performance data. Test samples are produced under third-party oversight to prevent hand-picked sample bias, including through audits performed by our fellow member company, Kiwa PI Berlin.

Four principles have guided the PQP since it was launched in 2012: the importance of using empirical data instead of assumptions; using standard processes for benchmarking across products; third-party witnessing of the PQP sample production to remove hand-picked, golden samples; and updating the PQP test plan regularly to keep it relevant to current module technology and manufacturing processes.

Key Takeaways from the 2025 Scorecard

In the 2025 edition of the Kiwa PVEL PV Module Reliability Scorecard, some test metrics show encouraging progress. For example, Potential-Induced Degradation (PID) and PAN (simulated energy yield performance) results improved. With PID, 72% of BOMs produced in 2024 degraded by less than 2%, an increase from the previous year. For PAN, we saw increased energy yields due to an increase in TOPCon and HJT BOMs included in the PAN dataset for the 2025 Scorecard, some of which had record-high energy yields. And encouragingly, more recent UVID test results are starting to show improved performance, indicating that manufacturers are actively progressing toward better UV stability in module designs.

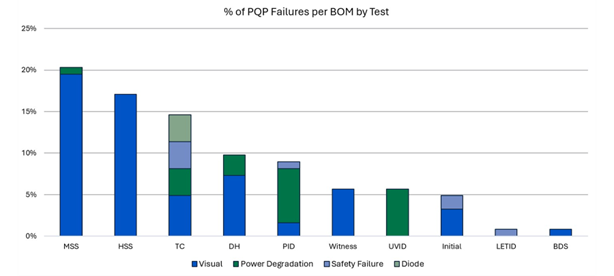

However, concerns arise elsewhere: module breakage during Mechanical Stress Sequence (MSS) and Hail Stress Sequence (HSS) notably increased, more modules failed under thermal cycling (TC) and damp heat (DH), and junction box issues and visual defects remain prevalent.

In this Scorecard, 83% of module manufacturers and 59% of BOMs experienced at least one test failure—the highest levels yet. The most prevalent failure type was visual defects, making up 60% of all failures, particularly from module breakage during MSS and HSS tests. Power degradation failures rose to 19%, driven by issues such as UVID, PID, thermal cycling, and damp heat. Safety failures, due to electrical insulation issues primarily caused by poor junction box sealing or pottant application, persisted at 7% of BOMs. Furthermore, about one-third of manufacturers faced junction-box failures, including falling covers, exposed wiring, diode issues, and melted connectors. And for the first time, 11% of manufacturers had “witness failures”, where modules weren’t shipped after factory witnessing due to quality concerns.

Why This Matters for Solar Stakeholders

Buyers need to be aware that not all modules are created equal. For developers, asset owners, financiers, and EPCs, the Scorecard offers trusted, empirical data to evaluate module durability to help reduce procurement risks and protect long-term investments.

The BOM-specific scoring ensures buyers can distinguish reliable combinations of materials and cells, including the concerns often overlooked by traditional certifications. In an industry pushing rapid innovation, the Scorecard can showcase failures even among otherwise certified modules. This highlights the need for extended testing to guard against field underperformance or hardware failures that cause safety or financial risks.

The Scorecard is a strategic tool for all solar developers that demonstrates the value of rigorous testing, BOM-level detail, and performance transparency. To learn more and access the Scorecard, visit scorecard.pvel.com.

2025 PV Module Reliability Scorecard

Contact Us

Would you like to know more about our services in the field of Solar? Please contact us using the form below.