AI Yard Inspections: How Kiwa is shaping safer, smarter inspections

In close collaboration with innovation partner SkyeBase, Kiwa is setting new standards in intelligent yard inspection services. Combining the use of drones, data and specialized AI technology with experience-based human insight, we can guarantee that even the largest industrial sites remain safe, efficient, and future-proof.

Across large industrial yards, such as container terminals, runways, and shipyards, safety and reliability depend on early detection of damage or wear. At Kiwa, we have taken yard inspection services to the next level. We are harnessing intelligent inspection technologies to deliver these services faster, safer, and with more precision. We do this by combining the versatility of drones with a powerful AI model that automatically identifies defects across large, complex yards. What was once a manual, high-risk process can now be completed in hours rather than days, with results that are more accurate than ever before – and without exposing staff to high-risk situations.

Covering every corner of the yard

For decades, yard inspections have relied on human visual checks, a time-consuming process relying on photographs and manual measurements. The accuracy of these methods can vary a lot, depending on factors such as accessibility or the experience of the individual inspector. ‘Drones, combined with artificial intelligence and expert human validation, provide a new level of consistency and precision,’ says Jaakko Tuukkanen, Global Business Development & Key Account Manager, Business Sector Digital & Cyber Solutions at Kiwa.

How semi-automated drone inspection works

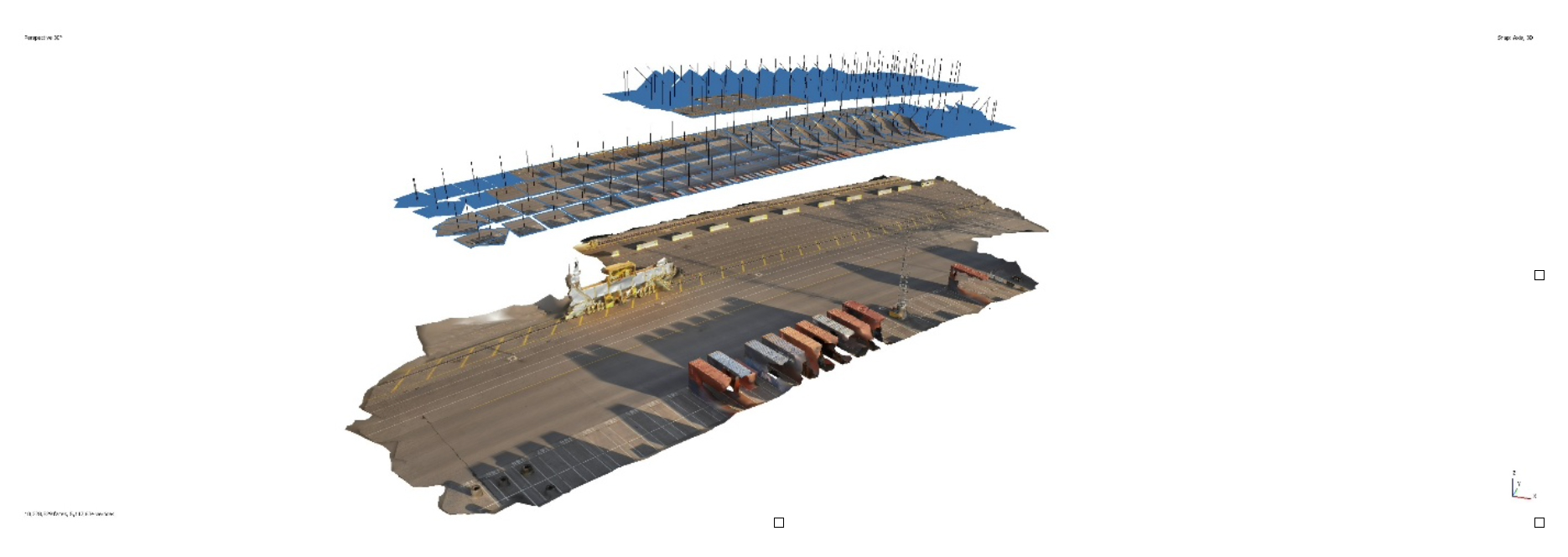

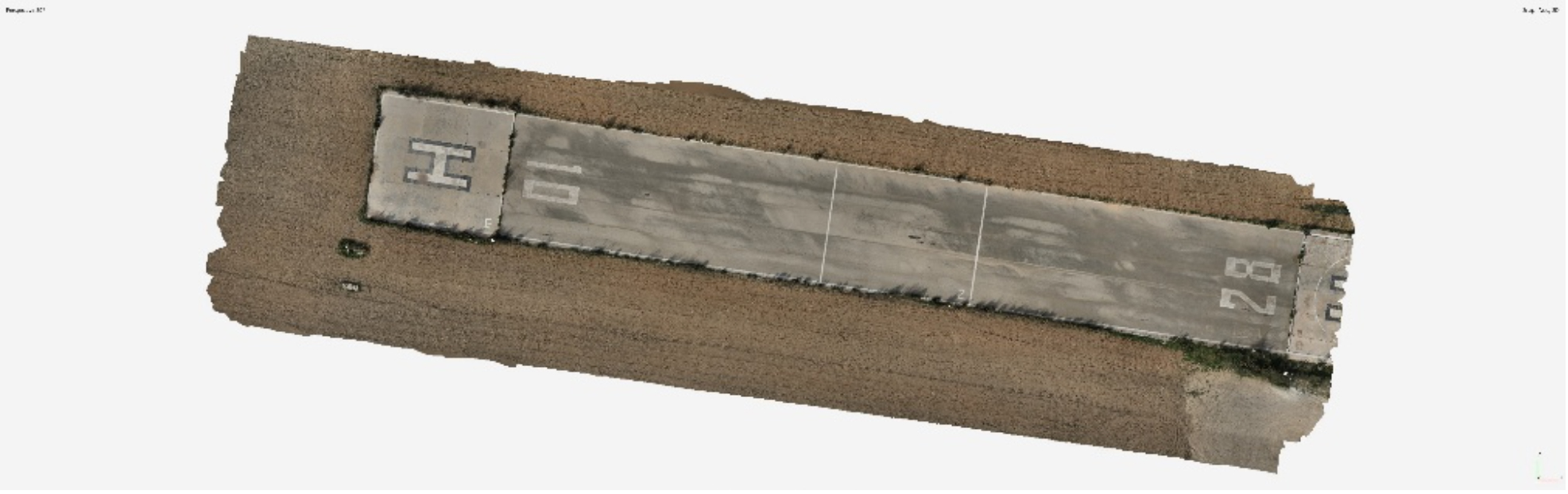

With the semi-automated drones we use for Kiwa’s intelligent inspection services, we scan your yard with high-resolution cameras to create orthophotos. These are large, geometrically accurate, true-to-scale representations of the environment. The drones fly at a specific height so that your activity can continue during inspection. This helps minimise interruptions to your day-to-day operations, and in some cases, such as runways, reduces the need for costly shutdowns. ‘The use of semi-automated drone technology removes the need for a physical inspector on site and speeds up the process without compromising accuracy,’ notes Jaakko.

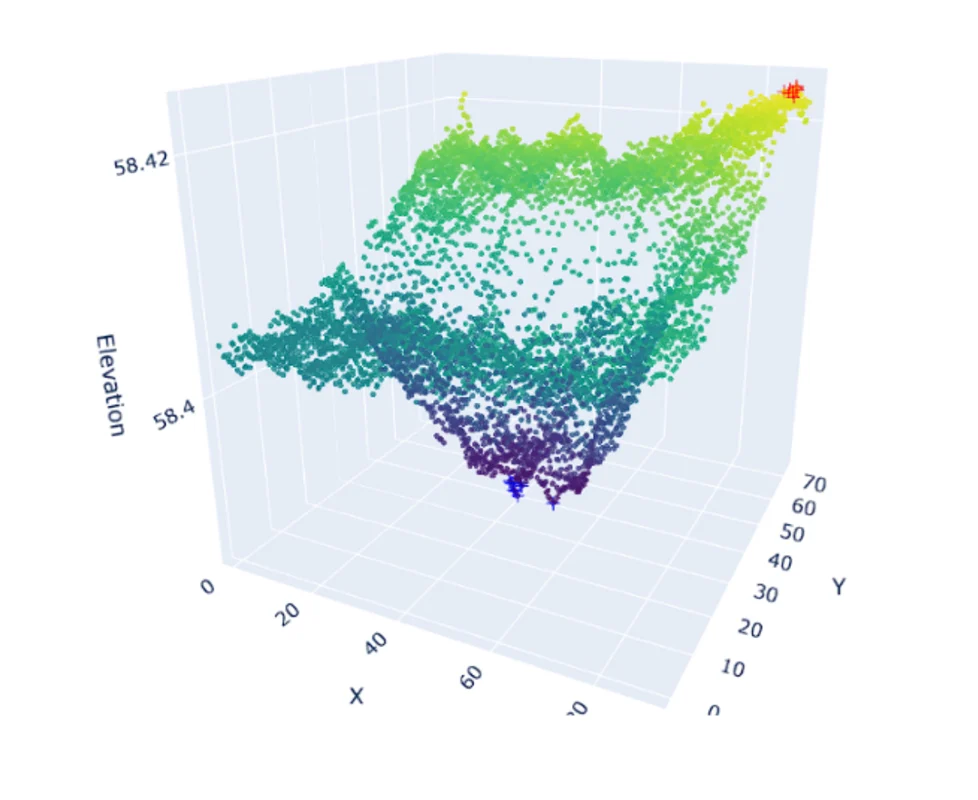

The data collected by the drones is processed with an AI defect detection engine. This AI tool analyses the images and automatically identifies cracks, potholes, and other forms of damage that may be invisible to the human eye. A Digital Elevation Model generates a 3D view of the terrain to measure pothole depth and accurately assess damage severity. The AI tool scans every image captured during a drone inspection and flags anomalies, distinguishing between different types of defects, and providing detailed insights. ‘Once the AI identifies potential issues, it creates an accurate risk assessment heatmap,’ explains Jaakko. ‘The heatmap clearly displays defect levels by means of colour grading. This means you can very quickly identify high-risk zones, prioritise your maintenance and prevent further damage and higher cost.’

Combining machine intelligence with human insight

Kiwa works closely with partners like SkyeBase, an intelligent drone & robotic inspections specialist. Tom Daniëls, CEO and co-founder of SkyeBase, highlights the key role of Kiwa’s inspectors in the collaboration. ‘These are experts who are experienced in reviewing and validating inspection findings,’ he comments. ‘This mixture of human insight and machine intelligence means we can ensure accuracy and consistency across every project.’ The verified results are compiled into a comprehensive inspection report, including high-resolution visuals, defect maps, and trend analysis over time. In the report, asset owners can see where maintenance is needed, prioritise repairs, and plan budgets more effectively.

Driving the decision-making process

An added feature is that the process is 100% digital, allowing for quick sharing of results and historical comparisons between inspections. This feature takes yard operators beyond next-gen defect detection toward better decision-making. ‘Over time, industrial yard operators can use the data we collect to track the progression of corrosion or surface damage,’ explains Jaakko. ‘It means that as an operator you can take the step from slow maintenance to efficient, predictive asset management – an approach that will deliver cost savings, reduce downtime, and improve operational safety.’

Setting a new standard for industrial inspections

The capacity of the AI engine used makes it stand out from other algorithms. ‘Standard systems cannot handle these volumes of industrial environmental data’, says SkyeBase’s Tom. ‘A standard AI model would have to divide an orthophoto of this size into smaller segments, which means you lose the context of the entire image. The more you zoom in, the more cracks would start to blur and disappear.’

What are the benefits of AI-driven yard inspections?

Here’s how AI-driven yard inspections can change the game for your company:

Fast & consistent detection

Cost & time savings

Minimal disruption

Data-driven decision-making

A type of data analysis not seen before in the industry

The AI system has been developed specifically for industrial environments. ‘We built a new architecture from scratch, training the model on industrial data and designing the neural networks to make multilayer predictions,’ says Tom.

Jaakko continues: ‘These predictions combine high- and low-resolution data, allowing the AI to dive deep while retaining context. At the same time, the system can process large datasets quickly and detect the smallest variations in texture or colour – possible indications of corrosion or structural weakness. This enables a type of data analysis not seen before in the industry. When Kiwa uses this technology, inspectors get a complete overview of potential risks before those risks become serious problems.’

Get in touch

Learn more about Kiwa’s Intelligent inspection services