Concrete Scan

Receive a quote tailored to your needs

The Challenge

Inspecting concrete structures such as bridges, industrial installations or buildings is an intensive, risky and expensive process. Due to complex shapes, tall structures and hard-to-reach areas, inspectors cannot always visually assess every critical spot.

Traditional inspection methods often require scaffolding or aerial work platforms, which compromises safety and can seriously disrupt the operation of a site. In addition, the manual approach often results in subjective and inconsistent analyses. There is no clear evolution of damage visible, so degradation or defects can go unnoticed until it is too late. This leads to higher costs for corrective maintenance and unforeseen downtime.

In a context where safety, sustainability and cost-efficiency are essential, the traditional inspection approach is clearly inadequate. The need for an accurate, safe and scalable solution for structural analysis of concrete is greater than ever.

The Solution

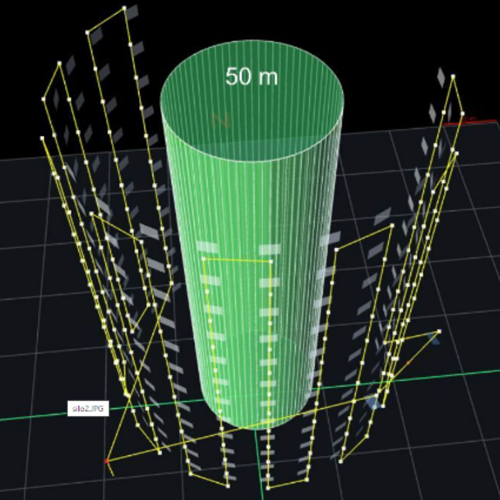

Kiwa offers an innovative inspection solution for concrete structures such as bridges, buildings, dams and industrial installations. With the help of drones, hard-to-reach areas are quickly and safely visualized, without the need for scaffolding or aerial work platforms.

The collected images are processed into a detailed 3D model on which cracks, erosion, coating problems and other defects are automatically recognized via artificial intelligence. This results in an objective, consistent analysis and allows for the monitoring of damage evolutions over time. The digital reports are clear and interactive, including filter options and trend analyses.

For in-depth technical investigations, Kiwa works together with concrete specialists who carry out inspections according to the NBN EN 1504-9 standard, including analysis of cover, reinforcement and concrete quality. Thanks to a mobile climbing robot, even vertical or hard-to-reach areas can be efficiently examined. In this way, we deliver a total solution that combines speed, security, cost efficiency and depth within one integrated workflow.

The Process

1. Layout of 3D models and semi-automatic data collection

2. Risk zone visualization and annotation

3. Digital reporting with filter function and defect comparison

Core Benefits of this Solution

- Fast and consistent detection of cracks, erosion and coating problems, even in hard-to-reach areas

- Defect analysis over time thanks to AI comparison of images; damage is assessed Quantified and visualized at the pixel level

- Optimized costs hrough efficient data collection, automatic analysis and targeted inspection planning

- Budgetable maintenance through clear mapping of defects and damage evolution

- Minimal operational disruption – inspections are fast, with no production downtime or scaffolding

The Impact

Fast and consistent detection

- Critical damage to concrete structures is detected early, which increases safety and longevity

- Automation and standardization reduce dependence on individual interpretations

Defect analysis over time

- Trend analyses show structural degradation at an early stage

- Pixel level comparison via AI prevents errors of judgement and ensures objective decision-making

Optimized costs through efficient planning

- Inspection costs are reduced by reducing the use of personnel, time and equipment

- Resources are targeted based on damage priority and risk analysis

Budgetable and plannable maintenance

- Defects become predictable, allowing maintenance to be planned proactively and cost-efficiently

- Insight into damage evolution supports both short- and long-term planning

- Maintenance budgets are clear and better substantiated towards stakeholders

Minimal operational disruption

- Inspections are fast and have no impact on daily operations

- Continuing operations, contributing to productivity and continuity