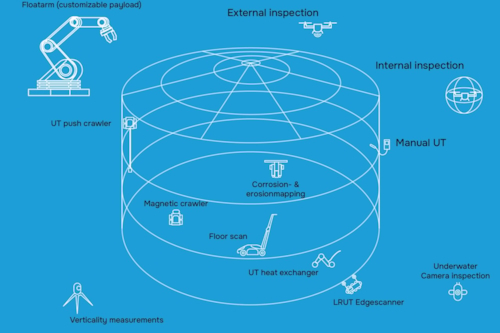

Kiwa provides advanced inspection services that integrate robotics, drone technology, and AI-powered analytics. This approach enables fast, safe, and compliant inspections, seamlessly supporting your general tank inspection program for both in-service and out-of-service assessments.

For tank terminals and in the process industry safety, compliance, and operational continuity are non-negotiable. Kiwa’s intelligent inspections complement traditional methods by bringing efficiency, safety, and clarity to your inspection programs. Through the use of drones, robotics, and AI-powered analytics, we help reduce costs, minimize risks, and deliver clear, actionable reports. With streamlined operations and advanced data capture and processing, you gain faster insights and stronger decision-making support.

Whether you're managing tank terminals, pipelines, pressure vessels, or flare stacks, our inspection solutions are built to meet the unique challenges of the process industry. We support:

Technology-Driven Efficiency

Using our digital platform, Kiwa delivers structured, multi-dimensional inspection data:

- Visual, thermal, and emission surveys

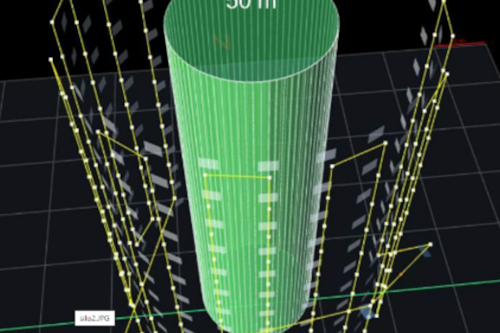

- Ultrasonic thickness measurements via drones (e.g. Elios 3 UT Payload)

- 3D defect visualization and AI-powered defect annotation

- Centralized reporting via digital dashboards or PDF formats

This integrated ecosystem enables predictive maintenance, trend analysis, and strategic asset management, helping you move more efficient.