Building Scan

Receive a quote tailored to your needs

The Challenge

Inspecting buildings today is a complex, time-consuming and costly process. Traditional visual inspections often require scaffolding or cherry pickers, which is not only expensive but also poses a safety risk for inspectors. Access to hard-to-reach roof and façade areas is often restricted, which means that significant damage is not documented or is incompletely documented. The subjective nature of manual checks also creates a lack of consistency and traceability in the assessment of damage over time. As a result, organizations run the risk of unpleasant surprises such as concrete and glass damage, erosion or structural degradation, which are noticed too late. In addition, these traditional methods disrupt the daily operation of buildings and infrastructure. In short, there is a need for an innovative and reliable approach that provides more insight into the actual condition of buildings, without compromising safety, efficiency or continuity of operations.

The Solution

Kiwa offers an advanced solution for building inspections that focuses on drones, 3D models and artificial intelligence. The drone flies around the building and collects razor-sharp images, even of hard-to-reach façade and roof areas, without the need for scaffolding or aerial work platforms.

These images are processed into a digital 3D model of the building. AI algorithms automatically recognize and classify cracks, erosion, concrete rot and other forms of damage. The report is fully digital and not only provides a snapshot, but also shows the evolution of claims over time, including trend analyses.

Even the most difficult areas can be efficiently examined thanks to a mobile climbing robot. This comprehensive approach delivers accurate, safe and efficient inspections, with minimal disruption to the day-to-day operation of the building.

The Process

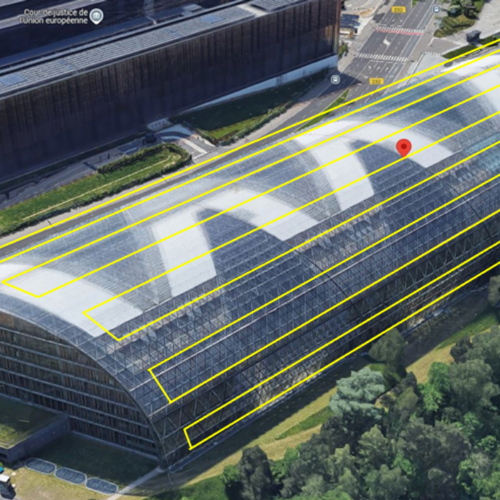

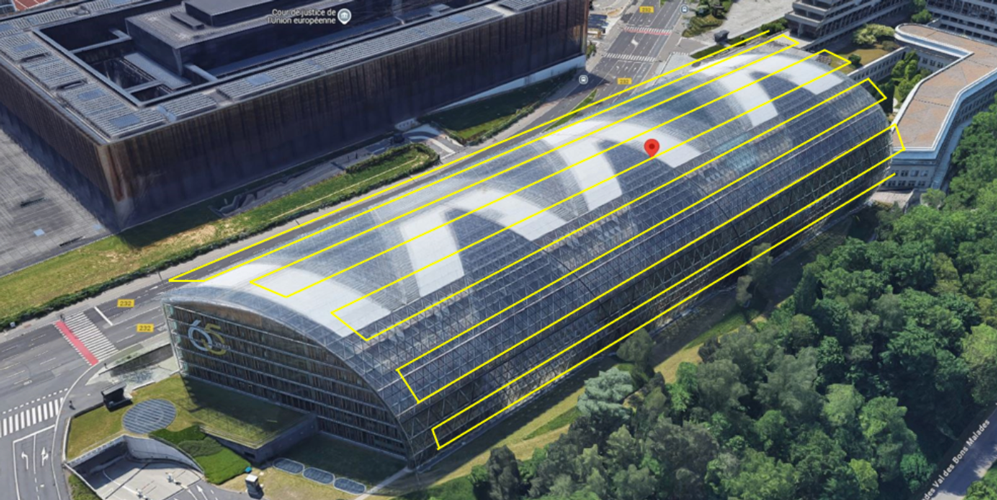

- Layout of 3D models and semi-automatic data collection

2. Visualization of risk zones

Core Benefits of this Solution

- Faster and more reliable damage detection increases safety and reduces risk

- AI analysis and image comparison ensure objective and consistent assessments

- Reduced costs through targeted inspection planning and reduced resource allocation

- Predictive maintenance makes budgeting easier and more efficient

- Minimal disruption to operation thanks to fast inspections without interruption

The Impact

Fast and consistent detection

- Defects are identified early, leading to increased building safety and reliability

- Automation reduces reliance on individual interpretations and ensures uniform inspection quality

Defect analysis over time

- Periodic comparisons make structural degradations visible more quickly

- Reliable AI analytics supports objective decision-making based on data-driven insights

Optimized costs through efficient planning

- Fewer man-hours, less equipment, and more targeted inspection cycles reduce overall cost of inspection

- Resources are targeted on the basis of real risks and damage evolution

Budgetable and plannable maintenance

- Predictability of maintenance needs makes it possible to plan costs in a staggered manner

- Managers can make informed choices about interventions and investments

Minimal operational disruption

- Inspections can take place without a production or use stop

- Operation of buildings and facilities remains undisturbed, which contributes to customer satisfaction and continuity